Great news – on this purchase, you'll enjoy a BuildBUX bonus of $9.99.

You probably already know that you want an intercooler with maximum cooling and minimum restriction for your Subaru WRX, but when it comes to selecting the right ‘man for the job’, we think it’s important to understand why. As air is pressurized by your turbo, it heats up, not because of the heat of the turbocharger, but because when they’re compressed, the atoms in the air are forced closer together and as a result, move faster and have more energy. That energy manifests itself as heat. The more heat we can remove from the system, the denser the air becomes and that’s what helps eliminate pre-detonation, or ‘knock’, allowing for increased output from your system. Your OEM TMIC does just fine at stock boost under normal use, but as soon as you start putting some real heat into it with higher boost or harder use, it heat-soaks beyond recovery.

Part #: 090010

Quick Specs:

Design:

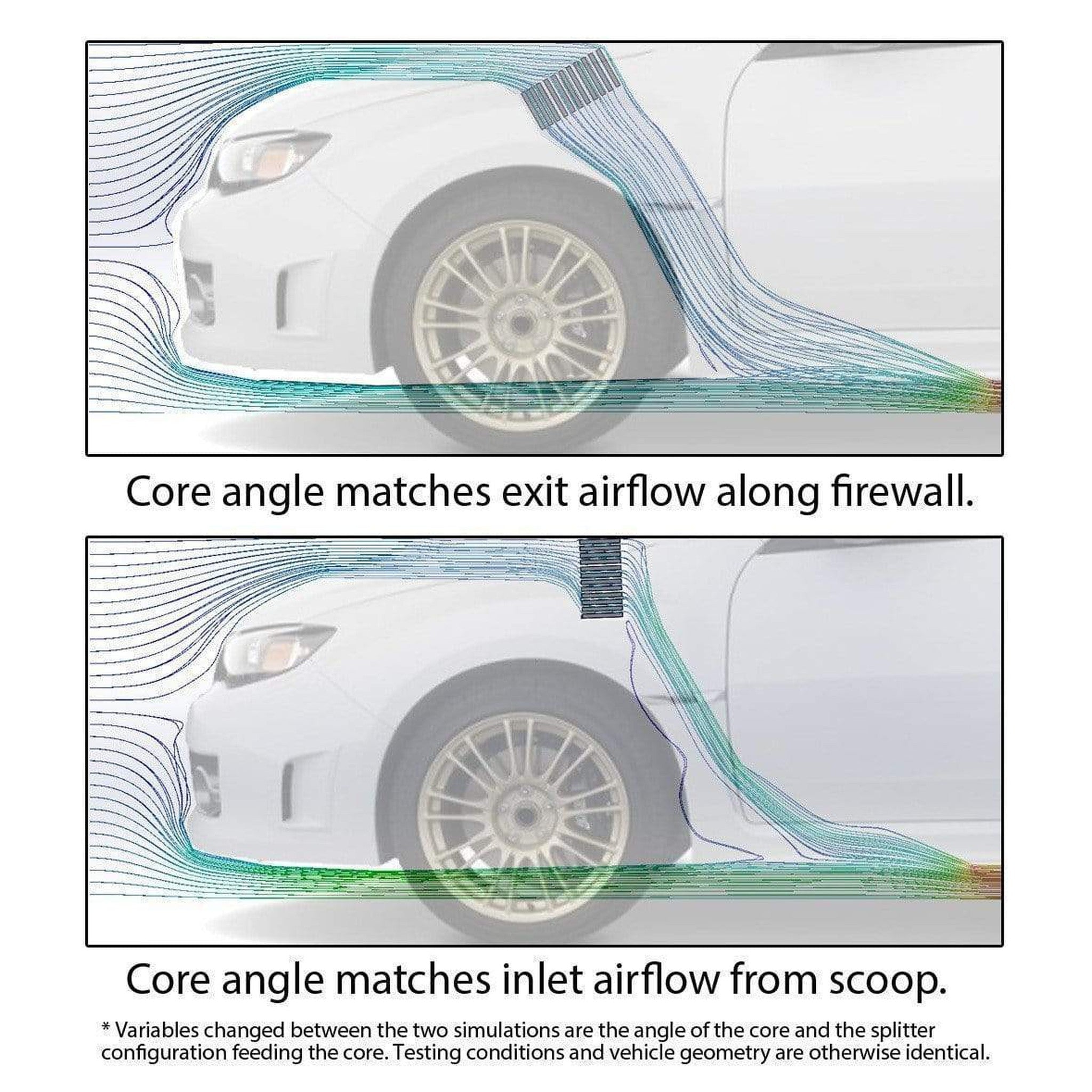

There are two primary considerations in the design of an intercooler: maximum heat transfer and minimum pressure drop. Unfortunately, one causes the other, so finding a perfect balance requires a detailed understanding of the intended application, some serious engineering power and the highest quality manufacturing processes. Fitment and quality are also critically important to ensure that the most safety-critical part of your turbo system is up to the task every time your foot hits the floor. We began by laser scanning an OEM TMIC to plot the mounting points and space claim in CAD with pinpoint accuracy. At the same time, we designed a custom bar and plate core with overall dimensions, fin density and fin types that would provide the insane heat transfer area we require with minimal flow restriction. With core size nailed down, we got to work designing end tanks that offered smooth flow, perfect fitment and even distribution of the hot charge air through the core. Countless revisions were tested in flow simulation before we finally found exactly the characteristics that we wanted. From there, 3D printed prototypes were used to confirm fitment and we began work on manufacturing details in preparation for verification testing and production.

Construction:

Each intercooler uses two unique end tanks. The first accepts the hot charge air from the turbo and feeds it to the intercooler core. The second receives the cooled charge air from the core and delivers it to the throttle body. These end tanks are precision cast and machined right here in Minnesota. The bypass valve flange is milled flat and stainless steel studs are permanently installed to ensure that the aluminum threads don’t become damaged and shorten the life of the intercooler. Following inspection, end tanks are welded to high density bar and plate intercoolers before the entire assembly is pressure tested, cleaned and sealed for shipment. 5-ply silicone couplers hold their shape in extreme conditions and ensure that charge air makes it to and from the intercooler with no trouble. Splitters are laser cut from aluminum sheet and CNC bent before being assembled and powdercoated with a durable texture black finish. Stainless steel hardware secures the splitter to the factory hood scoop.

More Cashback

Get more cashback! Items are changing weekly. Anywhere from 1% to 20% Back in BuildBUX when you make purchases. Products

Free Money

Every month when you are charged your $4.98 subscription fee, you will get $15 in BuildBUX

Easy To Cancel

Cancel anytime, month to month terms.

Cashback

Get 1% back on every purchase on eligible brands.

Free

Completely free to use. Just place an order!